Political instability, environmental disasters, pandemics, and even trade policy changes can destabilize global supply chains, as today they involve a vast network of actors – including raw material suppliers, manufacturers, transporters, and retailers. Each actor can operate under different regulations, economic conditions, geographies, and time zones. This interconnected web makes optimizing logistics operations complex and challenging.

With data generated across multiple stages and partners, global supply chains often suffer from fragmented information. The lack of a unified data-sharing platform complicates decision-making and makes it difficult to have continuous visibility into the entire supply chain.

Given the global reach and sophistication of supply chains, businesses require integrated solutions that provide visibility, data-backed insights, and predictive analytics to stay ahead of disruptions, optimize operations, and maintain efficiency.

Harnessing technology and data through Logistics Intelligence unlocks the power to solve even the most complex supply chain puzzles, transforming uncertainty into streamlined efficiency and strategic clarity.

Let’s explore how Logistics Intelligence tackles some of the most pressing challenges in global supply chains, turning obstacles into opportunities for efficiency and growth.

Challenge 1: Global Disruptions and Uncertainty

It’s happening!

Stuff is getting expensive.

Things are getting delayed.

Goods are in serious shortage.

And COVID, has only catalyzed the above trends.

Global supply chains are vulnerable to disruptions caused by events such as pandemics, natural disasters, trade wars, and geopolitical tensions. These unpredictable events can impact the smooth flow of goods, causing delays, increased costs, and inefficiencies.

Whether it’s the COVID-19 pandemic, which paralyzed manufacturing and transportation worldwide, or trade wars that resulted in sudden tariff hikes and regulatory changes, these disruptions expose the fragility of global supply networks. The effects cascade across regions, impacting lead times, inventory levels, and delivery schedules while creating uncertainty for businesses and consumers alike.

How Logistics Intelligence Solves Global Disruptions and Uncertainty

Logistics Intelligence enables scenario planning and risk mitigation strategies like route optimization, carrier management, inventory management, demand forecasting, monitoring shipping health and gaining control with overall supply chain visibility.

Challenge 2: Lack of Supply Chain Visibility/Transparency and Overcoming Information Silos

Businesses often struggle with difficulties in tracking shipments, especially when goods are in transit across multiple regions, transported by different carriers, or crossing international borders. Delays, missed delivery deadlines, and a lack of real-time updates on shipment status can lead to inefficient inventory management, customer dissatisfaction, and costly disruptions.

Moreover, visibility gaps extend to the tracking of suppliers and production status. Companies frequently work with multiple suppliers spread across different countries, each facing its own operational challenges, such as labor shortages, raw material delays, or production issues. Without clear insights into supplier performance, businesses face difficulties in forecasting potential bottlenecks and proactively resolving issues. This lack of transparency increases the risk of cascading delays throughout the supply chain, which can affect downstream production schedules and inventory levels.

Information silos can emerge when different parts of the supply chain rely on incompatible systems or outdated manual processes, making it harder to share timely, accurate data. This can result in misaligned priorities, decision-making based on incomplete information, and difficulties in coordinating responses to unforeseen events.

Limited visibility also makes it harder for businesses to track key performance indicators (KPIs), such as on-time delivery rates, production cycle times, and overall efficiency. As a result, decision-making becomes reactive rather than proactive, with organizations constantly scrambling to address problems as they arise instead of preventing them. To thrive in this environment, businesses need Logistics Intelligence tools that offer comprehensive, real-time visibility across the entire supply chain.

How Logistics Intelligence Empowers Businesses with Supply Chain Visibility

Case Study: How Markforged Streamlined Their Multi-Carrier Shipping Data to Improve Supply Chain Visibility

Problem: When working with multiple parcel shipping companies, extracting parcel spend information from each of their dashboards was getting complex and time-consuming. Their biggest challenge was data visibility.

Outcome: Markforged synced their carrier accounts with the Sifted platform to get all their shipping information in one place. By doing this they saved $10,622 from service failure refunds in less than a year. Markforged also reduced their late payment fees by $10,822.

Solution & Implementation: Markforged used the Spend Trend Summary dashboard to break down their spend with both UPS and FedEx. They also used Package Level Details to drill into all package and charge level details, including invoice number, tracking number, carrier details, shipping date, charge type, etc.

Challenge 3: Sustainability and Ethical Sourcing

Consumers, investors, and regulators are demanding that companies minimize their environmental footprint by reducing carbon emissions, eliminating waste, and ensuring responsible use of natural resources. Beyond environmental sustainability, there’s also a growing demand for transparency in how goods are sourced, ensuring fair labor practices, humane working conditions, and compliance with international human rights standards.

However, these expectations are often difficult to meet, especially within global supply chains. Tracking sustainability efforts across such vast networks is complex. One major challenge lies in monitoring and verifying environmental impact at every stage of the supply chain, from sourcing raw materials to manufacturing and transportation.

Similarly, ensuring ethical sourcing is complicated by the number of intermediaries involved. Businesses may lack visibility into the working conditions at supplier facilities, particularly in regions where labor laws are lax or not enforced. This leads to challenges in verifying compliance with ethical standards, such as fair wages, safe working conditions, and the prohibition of forced or child labor. Furthermore, even if the original supply chain is ethical, the actions of third-party suppliers several tiers down the chain may still be opaque, posing reputational risks for businesses.

Another obstacle is the lack of standardized frameworks and metrics for sustainability tracking. With no universally accepted criteria, businesses struggle to measure and report their sustainability efforts consistently across the globe. This makes it difficult to compare progress, identify areas of improvement, and ensure compliance with international environmental and ethical standards.

How Logistics Intelligence Helps Supply Chains Achieve Sustainability

“A big part of shipping sustainably is optimizing zones.”

-Caleb Nelson, Co-Founder of Sifted

Believe it or not, sustainability and cost reduction go hand in hand. When you ship from a lower zone, several positive outcomes occur, both in terms of sustainability and cost reduction:

Lower Shipping Costs: Shipping within a lower zone (shorter distance) is generally less expensive because carriers like FedEx and UPS charge based on the distance between the origin and destination. By shipping from a more localized fulfillment center, the cost per package decreases.

Reduced Carbon Emissions: Shorter shipping distances mean fewer carbon emissions, as less fuel is required to transport the goods. This directly contributes to a lower carbon footprint, making the shipping process more sustainable.

Faster Deliveries: Shipping within a lower zone reduces transit time, allowing customers to receive their packages quicker, enhancing customer satisfaction.

Reduced Risk of Damage: With less time in transit and fewer handling points, there is a reduced risk of damage to packages, leading to fewer returns and better overall delivery reliability.

Supply Chain Possibilities: How to Discover Operational Savings Using Logistics Intelligence

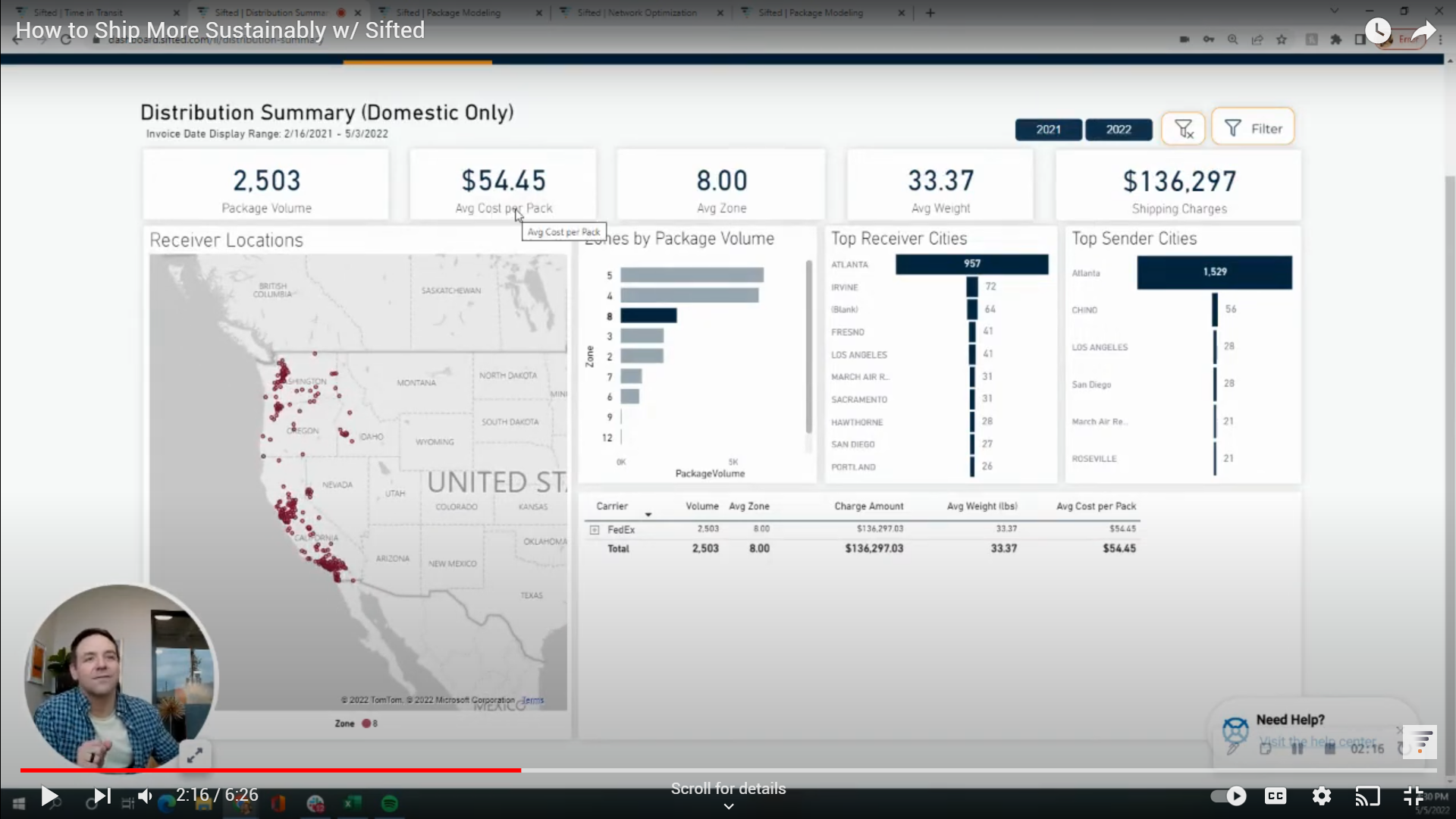

Zone 8: $54.45 Avg Cost Per Pack

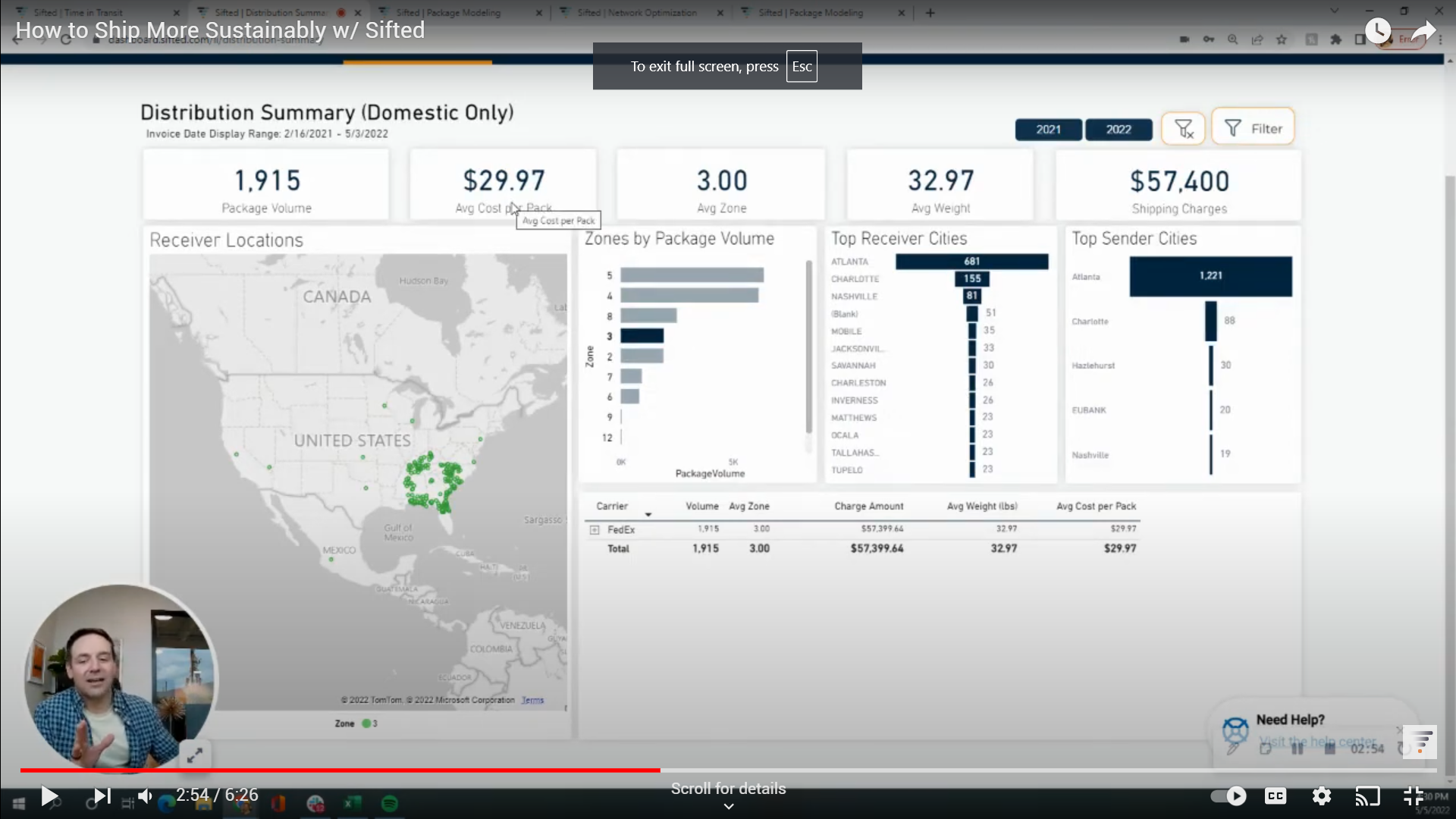

Zone 3: $29.97 Avg Cost Per Pack

In this example, you can see that the shipper pays $24/package less to ship in zone 3 vs. zone 8. By using Logistics Intelligence tools, they found that they could save big by lowering their zone. They could then use Sifted’s Network Optimization to find where the best location for a new distribution center would be.

Challenge 4: Technology Integration and Data Overload

From customer interactions and IoT devices to supply chains and social media – everything has become a source of data for businesses today. While this abundance of data presents huge potential for insights, it can also lead to several issues such as:

Unstructured Data: A significant portion of this data is unstructured—emails, documents, images, or social media posts—making it more difficult to process using traditional tools.

Volume and Complexity: As large sets of data accumulate over time, the sheer volume makes it hard to manage, store, and analyze using legacy systems. This leads to slower decision-making, inefficiencies, and missed opportunities for real-time insights.

Data Quality: When handling data from numerous sources, ensuring accuracy, consistency, and reliability becomes another challenge. Poor data quality can lead to misinformed strategies and decisions.

Lack of Interoperability: Many older systems weren’t designed with the scalability and flexibility required to support modern technologies. Legacy systems may struggle to handle the complex algorithms of AI, the massive influx of data from IoT devices, or the decentralized nature of blockchain.

Data Fragmentation: For AI or IoT to be effective, they need access to vast, interconnected datasets. However, legacy systems create fragmented data landscapes, limiting the effectiveness of these technologies in providing real-time, actionable insights.

Cost of Modernization: Modernizing or overhauling legacy systems to accommodate new technologies can be expensive and time-consuming. Businesses need to plan how to phase in new technologies without disrupting current operations.

Cybersecurity Risks: Emerging technologies can introduce new vulnerabilities, especially when linked to outdated systems that may not have the same security protocols. IoT devices, for example, can become an entry point for cyberattacks, particularly when connected to older networks with insufficient protection.

How Logistics Intelligence Manages Data Overload

Data Normalization: Data normalization is a key process in Logistics Intelligence where large amounts of data from various sources are standardized to provide a consistent format. This is critical because logistics systems often receive data from different devices, locations, or platforms, each using different units of measurement, data structures, or terminologies.

Data consolidation platforms offer unified visibility and insights to address this issue by gathering, organizing, and normalizing these diverse data streams into a standardized format. By ensuring data consistency and accuracy, these platforms make it easier to perform cross-platform analysis, reduce redundancies, and uncover actionable insights.

Need Help Cracking the Code to Your Supply Chain Problems?

With Sifted’s advanced Logistics Intelligence, solving your supply chain challenges becomes simpler and more efficient. From visibility to predictive insights, our platform helps you optimize every aspect of your operations.

Request a demo today and discover how Sifted can transform your supply chain strategy.