What is order fulfillment?

Order fulfillment is the process that enables companies to complete their customer orders successfully. It includes all the activities from when your inventory reaches the warehouse to when it is delivered to the customer’s doorsteps.

The order fulfillment process involves receiving inventory, storing inventory, processing orders, shipping orders, and handling returns. All these activities must happen for the successful fulfillment of customer orders.

Many businesses outsource their order fulfillment to a third-party logisticscompany for various reasons. These include a lack of in-house bandwidth, resources, or experience.

3PL warehouses are a key element in the supply chain of many companies. In fact, the global third-party logistics market is estimated to reach $1.3 trillion by 2026.

In this article, we’ll review the steps involved in the order fulfillment process when you hire a third-party logistics company to handle your picking, packing, and shipping.

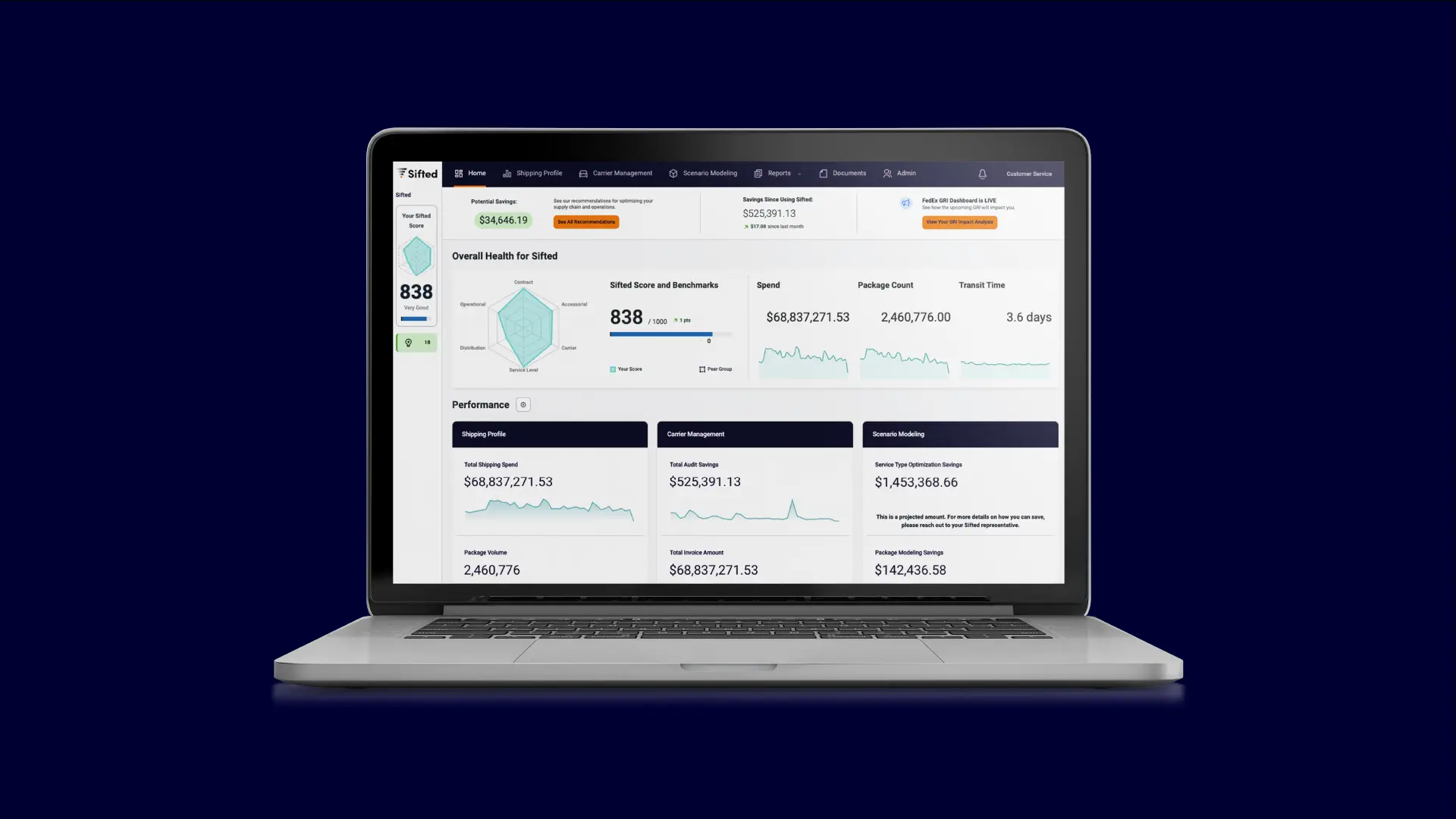

Are shipping charges catching you off guard? Gain full visibility into your supply chain operations with Sifted’s Logistics Intelligence solutions.

The Fulfillment Process

Efficient order fulfillment can help you lower shipping fees, increase shipping speeds, and make customers even happier. Below are the six steps involved in the order fulfillment process:

1. Inventory is delivered to your fulfillment center.

The first step in order delivery involves the fulfillment center receiving goods from the manufacturer or supplier.

Manufacturers transport the ordered shipment to the fulfillment center in a truck or through a small parcel delivery service like FedEx or USPS along with shipment details.

In contrast, resellers or drop shippers route their customer orders straight from the customers to their suppliers. The supplier then sends the ordered shipment along with the order details (including the customer address) to the fulfillment center.

2. Your fulfillment company sorts your goods.

After the shipment is transported to the fulfillment center, the receiving staff:

- Count the product quantity received at the facility.

- Check for any damaged or spoiled items.

- Add SKUs or barcode labels to the warehouse management system for easy tracking of location, quantity, and product categories.

A warehouse management system (WMS) helps businesses stay updated with their inventory requirements. It also helps warehouse staff automate manual processes, increases order accuracy, and gain visibility into supply chain operations from the fulfillment center to the customer.

Once all the received goods have been properly checked, inspected, labeled, and added to the fulfillment center’s WMS, they are shelved in warehousing storage equipment such as pallet racks, bins, and storage cabinets.

3. Inventory is stored by your fulfillment company.

Accurate and efficient inventory storage is essential to the success of the fulfillment process.

Most fulfillment centers are optimized to speed up order processing. For example, they use technologies from machine-readable barcodes for labeling storage bins and picker robots for autonomously retrieving and carrying products in a warehouse.

Fulfillment services use warehousing management systems to organize inventory around the warehouse. To optimize space usage near the order packing station, only a portion of a shipper’s total inventory is stored in storage bins, and the bulk of the storage is shelved in other parts of the warehouse.

Similarly, high-demand products are stored near the packing stations to increase efficiency. These positions are updated as the demand for different products changes over time.

4. Customer orders are routed to your fulfillment company.

After all, the received items have been inspected, sorted, and inventoried, they are ready for order management and processing.

The fulfillment center receives customer orders either directly or from the vendors. Its integrated order processing management system also receives orders from the online sellers’ website or an eCommerce marketplace.

5. Your fulfillment center processes and ships your orders.

Businesses that outsource their order fulfillment to a third-party logistics (3PL) company don’t have to worry about finding, picking, and packing the ordered products and preparing them for delivery. The fulfillment center’s staff does it for them.

Once the fulfillment center gets an order, the staff picks individual items from the storage locations and delivers them to the packing stations. The ordered items are then checked for accuracy and quality, scanned, and properly packed to meet shipping requirements such as safety in transit and branding. Packaging is optimized to target low shipping rates based on DIM weight pricing.

You can calculate the DIM weight pricing for your packages using this handy DIM weight calculator.

A 3PL fulfillment company leverages its high volume shipments to negotiate the best prices from carriers and pass on the discounts to their customers.

After the ordered items are packed, it’s delivery time. The packaged items are then handed over to a shipping carrier, like UPS or a regional carrier. Delivery time will vary depending on the shipping options chosen by the shipper. The carrier informs the sellers and customers about the order status through order tracking.

Finally, the ordered items are delivered to the customer’s doorstep by the carrier.

6. Your fulfillment center processes customer returns.

Once the orders are placed and products are picked, shipped, and delivered, you wait for customers’ feedback. This is a critical part of the order fulfillment process. As a seller, you need to ensure the right items are delivered to the customer in the best condition at the promised time. If the package arrives late or if it is an incorrect package, you may have to reimburse the customer. This part of the order fulfillment process is called reverse logistics.

Depending on your return policy, the customer may request a return, exchange, or refund. Similarly, if the customer order is received from a marketplace like Amazon, you’ll need to follow their specific return rules.

Most fulfillment services handle returns for shippers. Their customer service department will communicate with customers to process return requests. This includes ensuring eligibility for returns. For example, ensuring that original tags haven’t been removed.

Customers can simply ship the items back to the fulfillment center, and the staff examines the package contents and condition. After you receive the inspection report, you can decide to issue a return, refund, or product exchange.

The Great Debate:

FBA vs. FBM

FBA Fulfillment Requirements

Amazon sellers enjoy many privileges including free shipping on your products, shipping discounts, and access to Amazon Prime customers. In addition to this, Amazon handles everything from order management, picking, packing, and shipping to customer service and returns management.

However, you need to follow FBA fulfillment requirements when sending your products to Amazon fulfillment centers. This ensures your products are accepted at the warehouse and delivered to your customers without damage.

Here are some of the most common FBA fulfillment requirements:

- Size: Use standard 40 by 48 inch pallets, and pallet height must not exceed 72 inches.

- Weight: The pallet weight must be less than or equal to 1500 pounds.

- Packaging Material: Bubble wrap must be used for breakable items and closed properly so that items don’t slip out. Poly bags and shrink-wrap must be used to protect items against dirt and humidity. Boxes and tape should be used to provide extra protection to packaging.

- SKUs: All items that are packaged together must have the same SKU. If you are selling a product that contains multiple items, you’ll need to package them together.

- Drop Test: Packages must pass a 3-foot drop test on a hard surface without breaking. This test ensures that product packaging can endure drops, rattling from trucks and conveyor belts, and compression from stacking boxes during shipping and handling.

- Labeling: Each product must have a scannable label visible on the packaging. The box label must contain:

- A scannable barcode

- A shipment ID

- Box dimensions and weight

- Quantity of each SKU

- Origin and destination addresses

Get a handle on your shipping data with Sifted

An order fulfillment service keeps you on top of your customer orders, gives you access to its dedicated staff for picking and packing goods, and enables you to deliver packages in good condition.

Sifted Logistics Intelligence gives you full shipping visibility across all your carriers in one place. You can run simulation models of how a new box-size impacts your shipping charges and get recommendations on how to optimize packaging to target lower rates.

Sifted gives you a better understanding of your key metrics like shipping charges by service type and package count to help you find the right shipping partner for your business.

eCommerce sellers use Sifted to establish realistic transit time expectations. Get a free demo from Sifted today!