It’s Monday morning, so you settle in for your favorite activity: analyzing your carrier report. You sit down with a fresh cup of coffee and start digging into the thousands of lines in your CSV document, meticulously searching for errors and missed opportunities.

Yeah, that’s not happening.

No one, and I mean no one, has time for that! When it comes to carrier reports, you can’t comb through them line by line, so it’s important to look at some key areas to better understand your shipping data and any costly mistakes you might be making.

Pricing

When it comes to carriers, it pays to shop around. You need to know which carrier provides the best pricing for your unique shipping profile. Factors like your most common service types, package weights, package dimensions and more all make up your profile, so you need to clearly understand it yourself to get optimal pricing.

If you’re splitting your shipping between carriers, you need to know that you are shipping enough with each carrier to get their best volume discount. You also need to know the pricing nuances for each carrier – not all charges are created equal. Only a clear understanding of your data will give you a true apples-to-apples comparison.

Packaging

Using the wrong packaging costs shippers a lot of money because there are so many factors that go into what carriers charge. Ask yourself:

- Is my packaging too big?

Packaging that’s oversized for the items inside will mean you overpay for the shipment because of the dimensional (DIM) weight. - Am I subject to additional fees because of my packaging?

If your packaging exceeds certain dimensions, you’ll pay more. For instance, with FedEx, if your packaging is more than 48 inches on the longest side or more than 30 inches on the second-longest side, you’ll pay an additional handling surcharge. - Am I getting billed for the correct dimensions for the box I shipped? Sometimes, your carrier will scan a box and say it’s a different size than it actually is, leading to higher costs. The DIM weight of a 13x13x12 box will be two pounds more than a 12x12x12 box. You need to watch for this in your carrier reports and dispute each occurrence.

- Are my pick-and-pack teams using the correct box for the item being shipped? Whether you have guidelines for which packaging to use for each item you sell or you leave it to the judgment of your packing team, using the wrong box can add up. One of our clients painstakingly weighed and measured all their SKUs – more than 1,000 items – and entered them into their management system, which then recommended the most economical box for shipping. But because so many of their box sizes looked similar, the warehouse staff was still choosing the wrong boxes. It proved to be pretty costly – a 48x20x18 box looks a lot like a 50x22x20 box, but the slight difference in dimensions creates an unnecessary 34 pounds in billed weight plus additional handling fees.

- Am I using the correct type of packaging? If your packaging is anything besides a squared cardboard box – like a tube, a plastic bag, or foam – it will be subject to additional fees.

Shipping speed

During the last several years, consumer expectations around shipping costs and speed have changed. These days, shipping has got to be fast and free. Fifty percent of consumers in a UPS survey said they had abandoned their cart because shipping costs were too high, and 62% of shoppers consider fast shipping a part of a positive retail experience. These heightened expectations have created a nightmare for shippers.

One way to keep customers happy while keeping your costs down is to make sure you have a handle on your carrier’s performance data. In one region, one carrier might be able to get a ground package hundreds of miles in two days through a more cost-effective ground service rather than a two-day express service. The same idea applies to next-day service – you might be paying for a more expensive service that’s unnecessary. If you understand how your carrier actually moves your packages, you’ll be able to select the right shipping service.

Free shipping minimums

When it comes to offering free shipping, it’s essential to know your landed cost – the total cost of moving a package to the end consumer – and ensure that is factored into your cost of goods sold.

Let’s say that you offer free shipping when a customer spends $50. If you sell five $10 items that each have a $3 profit margin, you are making $15 on the sale. However, if it costs you $17 dollars to ship the package, you technically lost $2 on the sale and are operating at a loss – not an ideal business model! If shipping makes up most of your business, you could get in trouble fast. At that point, you’ll need to carefully examine both your shipping policies and your cost of goods sold to ensure you’ve struck a balance between customer experience and profits.

How to take action

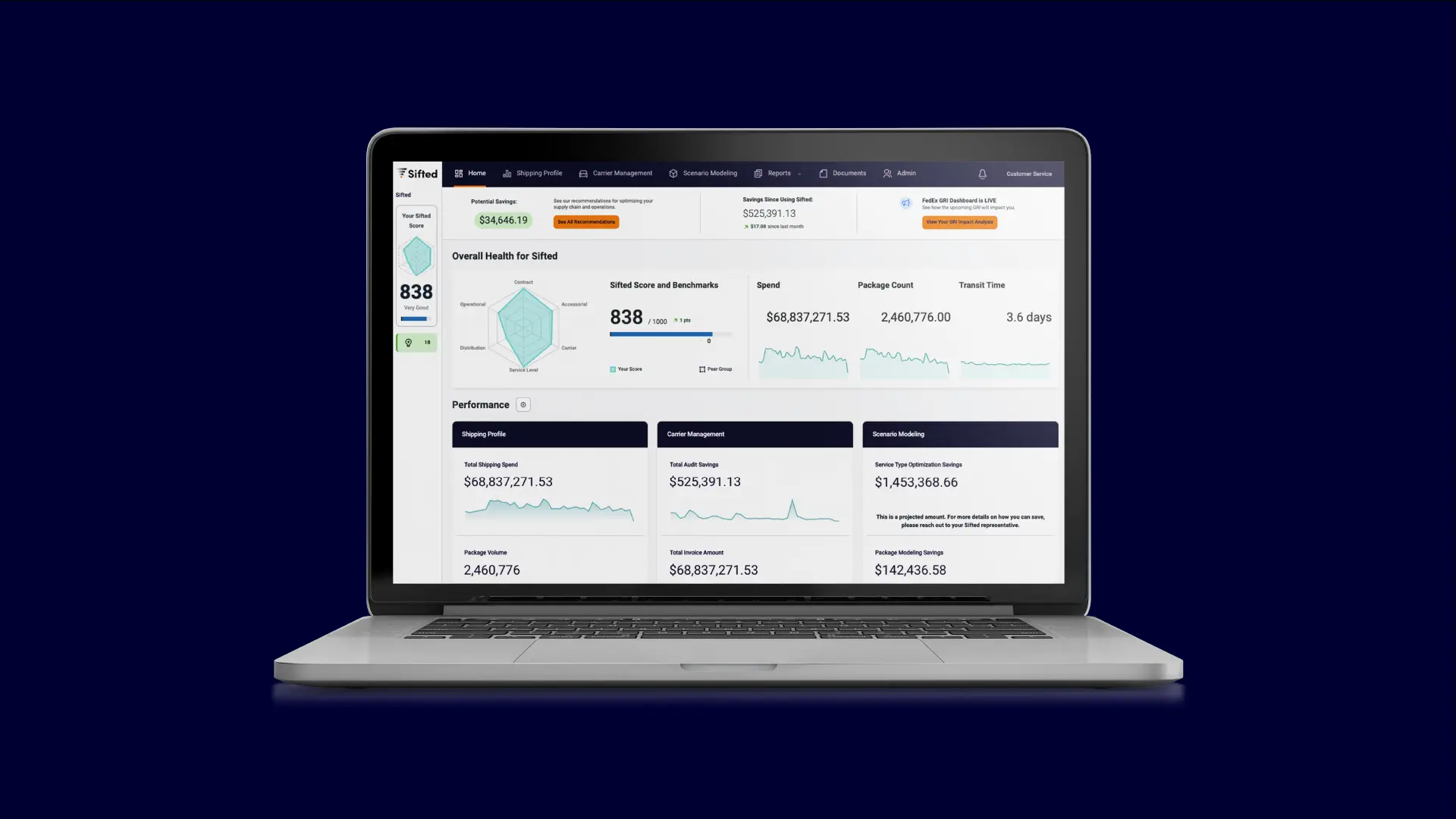

There are a few ways to combat overpaying by better understanding your shipping data.

- Look for patterns in the data that indicate repeated overpayment – like the same surcharges popping up over and over or a particular region that’s costing you more than others to ship to.

- Identify your top problem areas and work with your carrier to tighten up your carrier contract the next time you renew.

- Consider a third-party tool to analyze your data, identify trends and make recommendations for cost savings.

Your shipping data is a complex beast that isn’t easy to interpret. When you take steps to break it down, though, you’ll start to make progress in cleaning up your shipping practices, as well as other areas of your operations.

Wondering what other mistakes you might be making? Check out our white paper, Five Big Shipping Mistakes Your Company Is Likely Making.