Is it too much to expect a dependable, low-cost carrier service?

With tight margins, fierce competition, and demanding customers, logistics management has become a significant challenge for supply chain companies. Especially with growing supply chain demands and costs this pandemic season.

But, low-cost supply chains can become a norm if you know how to optimize your logistics systems.

How to build a resilient and successful supply chain

Supply chain management is a complex network of manufacturing and logistics systems involving a wide range of activities.

Organizing supply chains for resilience and robustness may seem impossible. But it can be achieved if you structure your supply chain activities for efficiency.

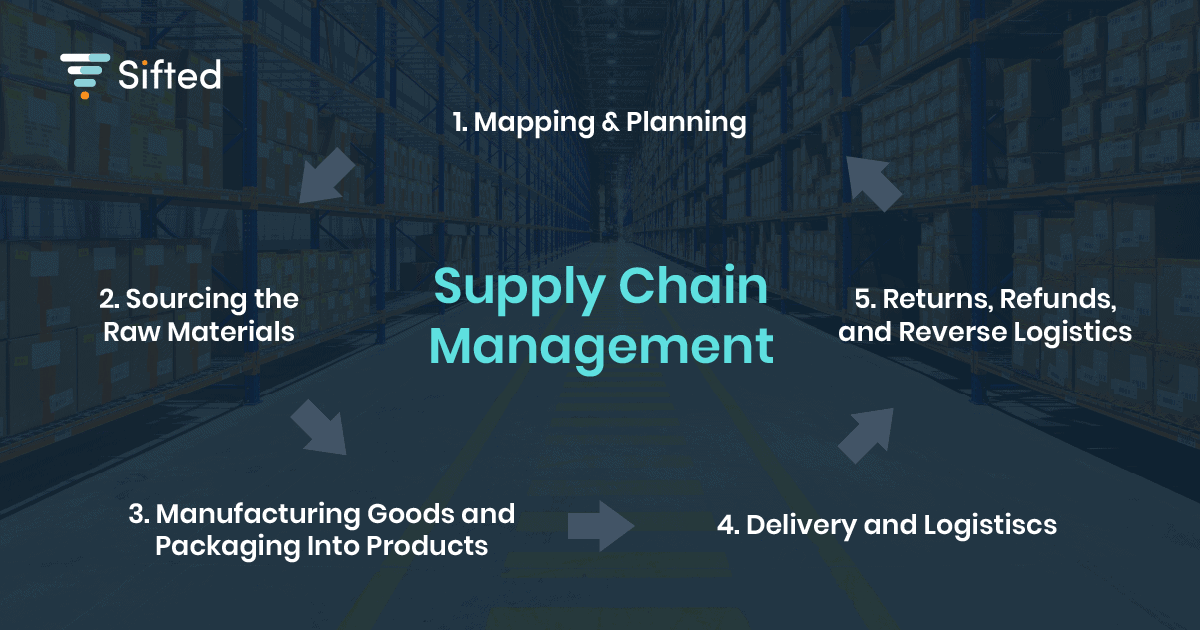

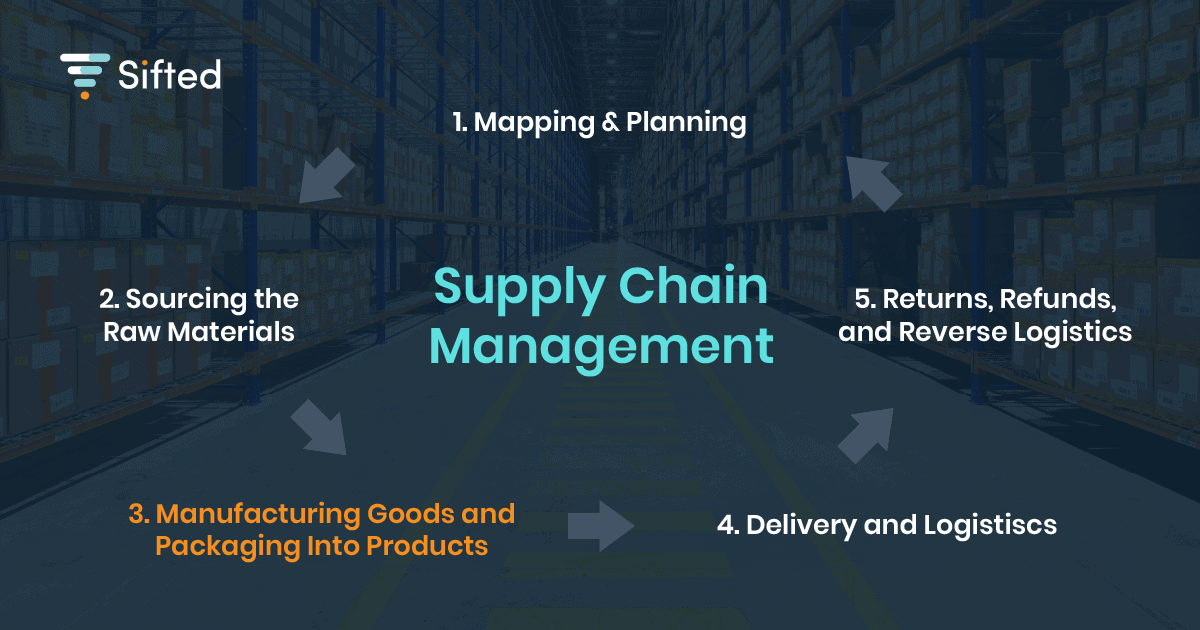

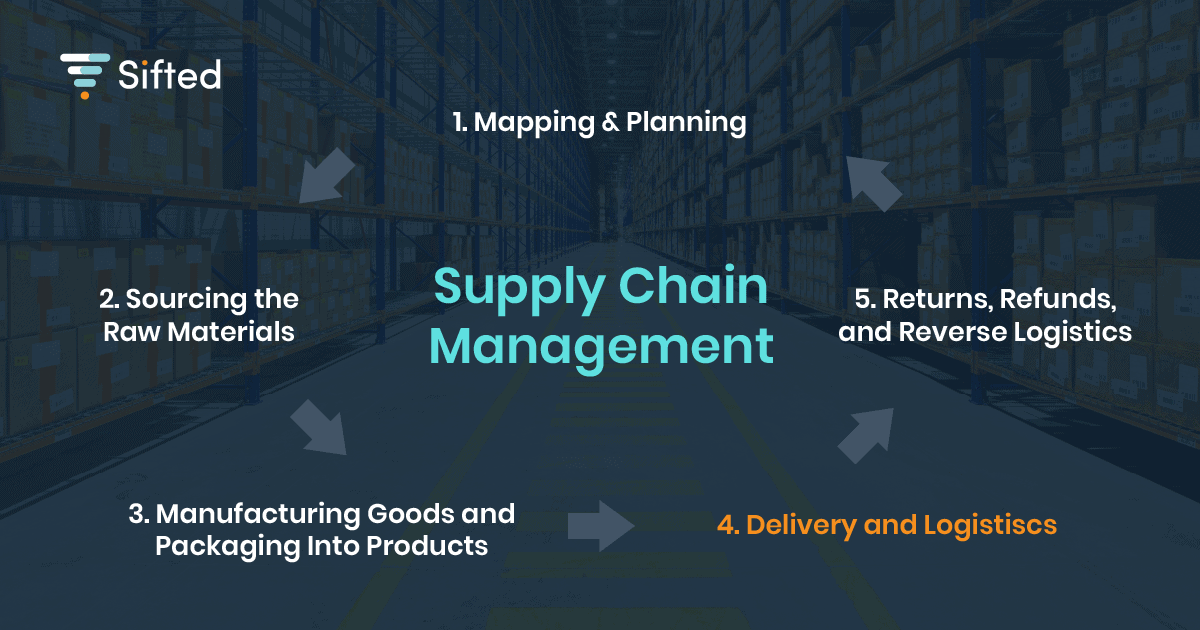

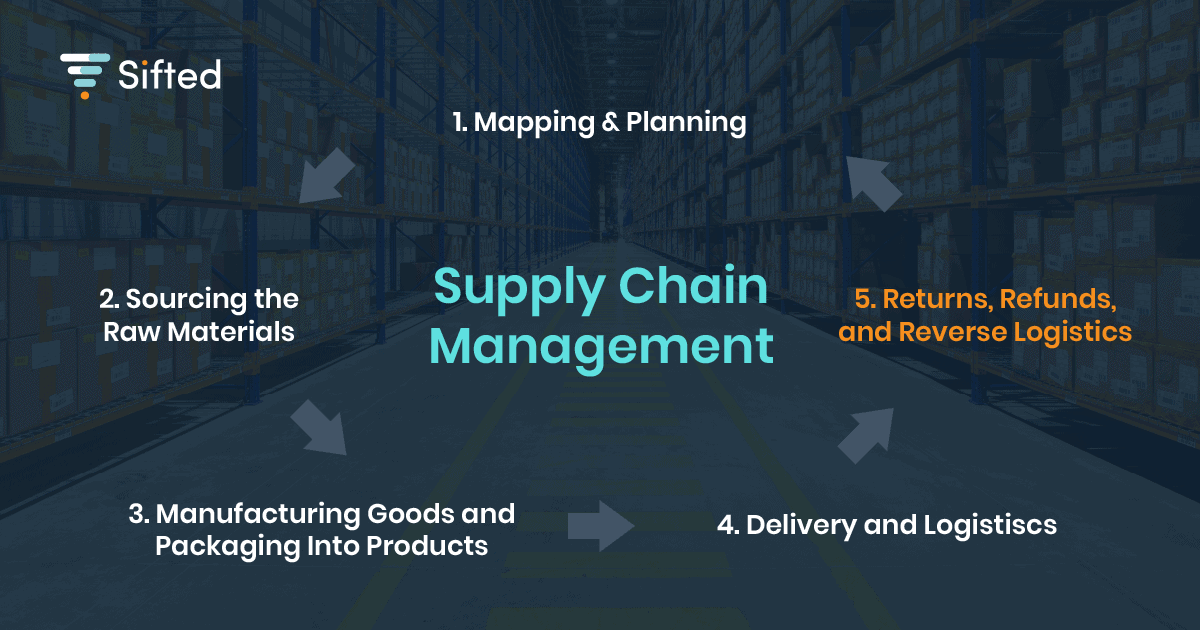

For simplicity and clarity, let’s break down supply chain management into 5 stages:

1. Mapping and Planning

2. Sourcing the Raw Materials

3. Manufacturing Goods and Packaging Into Products

4. Delivery and Logistics

5. Returns, Refunds, and Reverse Logistics

Stage 1: Mapping and Planning Your Supply Chain

Planning is the most crucial step. This is where you devise a supply chain operations strategy. But before you do that, identify your customer’s needs first, and establish a product-manufacture fit.

What is Product-Manufacture Fit?

Product-manufacture fit is a supply chain experimentation and mobilization strategy to minimize costs, mitigate risks and maximize profits. To create a supply chain experimentation plan, explore the manufacturing possibilities, raw material sourcing options, and optimize the processes to create a profitable and sustainable supply chain.

Stage 2: Sourcing The Raw Materials

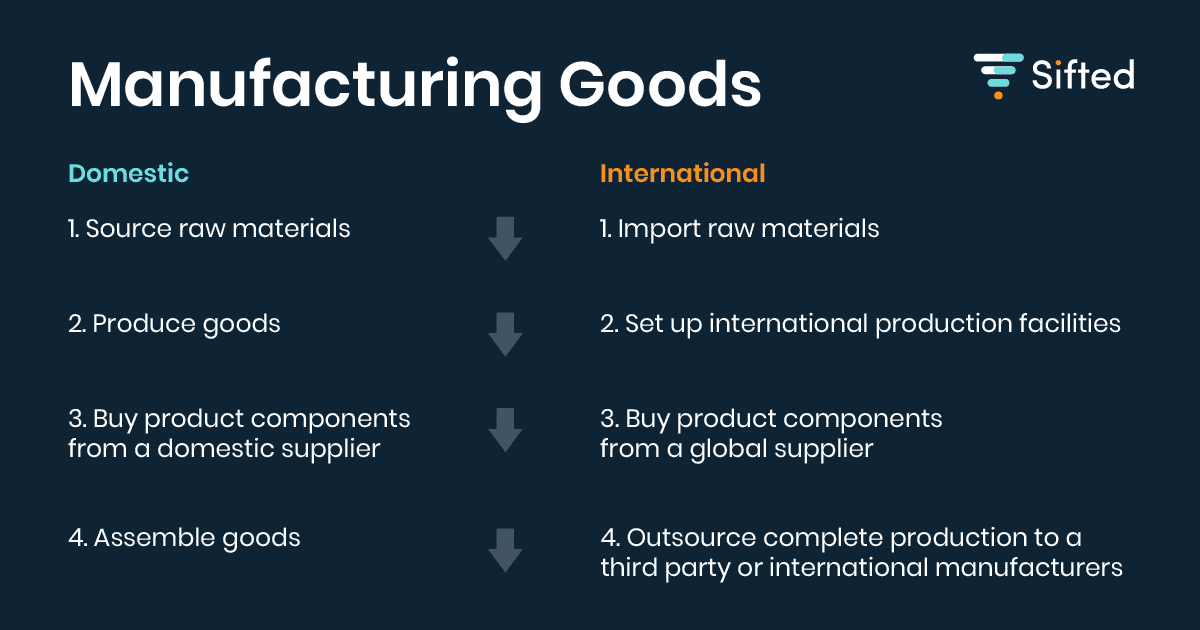

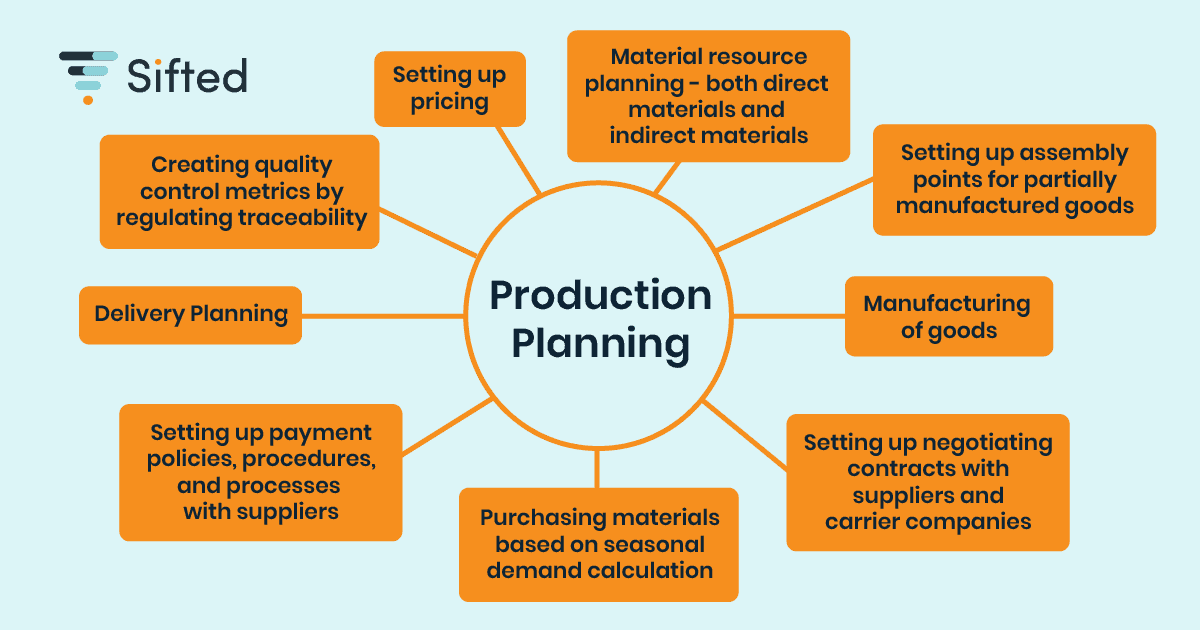

To begin, here are the steps and processes involved in manufacturing goods:

The next logical step is to choose the most optimal production plan and decide how your supply chain manages:

- Material resource planning – both direct materials and indirect materials

- Purchasing materials based on seasonal demand calculation

- Manufacturing of goods

- Setting up assembly points for partially manufactured goods

- Setting up pricing

- Delivery planning

- Setting up payment policies, procedures, and processes with suppliers

- Setting up negotiating contracts with suppliers and carrier companies

- Creating quality control metrics by regulating traceability

Stage 3: Manufacturing Goods and Packaging Into Products

Now that we’ve figured out sourcing raw materials and resource planning, it’s time to add value to the raw materials.

This process is called manufacturing.

Manufacturing and delivering a product on time, within the allotted budget is the number one goal at this stage.

As time goes on and technology advances, manufacturing systems and processes are becoming more and more complex.

Let’s look at this example: In the 18th and 19th centuries, the industrial revolution transformed economies because of the well-established relationship between customers and suppliers. In fact, The National Academy Press quotes:

“By 1920, well-developed relationships between customers and suppliers facilitated the emergence of ‘mass production.’”

And as we speak, mass production is at an all-time high. This brings us to the million-dollar question. Is it possible to manage such large-scale production units and complex supply chain management systems seamlessly?

The answer is yes.

Modern supply chains strive for tracking and reducing redundant supply chain steps and having more control over the manufacturing and operations processes. And they achieve this using business intelligence and advanced AI technology.

Quick note: A logistics intelligence system helps you tap into your supply chain’s mind and control its matter. Take proactive steps to optimize your modern supply chain operations by getting a complete overview of your business that saves you money. Request a free demo here.

Stage 4: Delivery and Logistics

Reducing product defects, increasing production efficiency, and delivering quality products on time to the customer is the end goal of any supply chain.

The process of direct/indirect integration of the products with the consumers happens in the delivery and logistics stage.

This can be further classified into the following steps:

- Receiving orders from customers

- Establishing a network of warehouses

- Choosing logistics partners to deliver the product

- Collaborating with 3PLs

- Setting up an invoicing and payment acceptance system

Stage 5: Returns, Refunds, and Reverse Logistics

The processes we spoke about up until now are categorized as forward logistics. Because they’re all headed towards the end goal – to deliver a product to the customer.

Once the customer files for a return, the processes that are triggered after this point are called reverse logistics.

What happens to a product after it’s filed for return?

Reverse logistics starts by tracking the products filed for return. They’re then categorized into:

- Defective

- Damaged

- Outdated products

- Low quality

- Wrong product

- Late delivery

- Over-purchase

- Recalled by government

The 5 stages of a supply chain system represent the high-level, big-picture decisions and tactical operational overview you can tap into to optimize your systems.

But to optimize your supply chain systems, you should first be able to identify the root causes that slow down the supply chain and contribute to revenue loss.

Factors Affecting Supply Chain Performance

715 supply chains were surveyed for research, and it was observed that the COVID-19 pandemic has disrupted 78% of these supply chains.

That’s a big number, and it shows how susceptible our supply chain systems are.

But, even on an average day, many factors are influencing your profits (or losses):

- Fuel Costs:

With escalating oil prices, logistics costs spiral upward as well. So to get to the root cause, what’s causing a spike in oil prices? Crude oil prices, refining costs, retail distribution, freight and processing charges, excise duty, and dealer commission are some of the factors that contribute to increasing fuel prices. - Delayed Shipment Arrival:

Out of the scope of delivery partners, shipments can be delayed due to various reasons. Bad weather (caused due to hurricanes, cyclones, etc.), piracy, regional wars, fire hazards, changes in traffic schedules (especially for inland traffic), etc., can cause shipment delays. Other than that, the primary reasons causing delayed shipments leading to increased logistics costs are shortage of containers, vessel space, and ships for transportation, especially after a holiday season. - Delayed Delivery:

Lack of delivery personnel or the unavailability from the end customer can cause delivery delays. In such cases, the product has to be stored in a warehouse. And this leads to an increase in warehouse charges. To reduce warehouse rental charges, several logistics partners prefer cross-docking their product line and deliver the product directly from the supplier to the customer, doing away with warehousing. - Government Regulations:

Rules of international trade are complex. Processing legal permit documents, compliance checks, and contracts add to the extra supply chain costs. Authorities impose these regulations at various levels like federal, state, and local. The anti-idling and other emission reduction regulations can cause a significant increase in annual compliance costs.

Let’s look at how we can leverage business intelligence in logistics to track and save these costs.

How To Use Logistics Intelligence To Track And Reduce Supply Chain Costs

Logistics Intelligence is nothing but supply chains using and simulating human intelligence processes, with the help of machines, to speed up their manufacturing systems, reduce churn, and increase their manufacturing rate efficiently by reducing their manufacturing cycles to a fraction.

Let’s look at an example.

Cisco is one of the largest and best supply chains in the world. In Gartner’s 2021 report, Cisco was rated the best supply chain leader for the second consecutive year. These rankings were based on the resilience, agility, and sustainability of the supply chains.

What did these companies do differently to thrive during a crisis like the Covid-19 pandemic?

They adopted the digital-first approach and employed business intelligence to automate and speed up the processes that require little to no maintenance, hence saving them millions of dollars in costs.

A survey of boards of directors taken late in 2020 showed that nearly 70% of companies accelerated their digital roadmaps, as compared to the beginning of the year.

Let’s look at the benefits of logistics intelligence.

How Logistics Intelligence Helps Improve Supply Chain Resilience And Agility

- Automates data collection processes and reduces human effort and time

- Identifies negative trends and controls costs effectively with a detailed overview of the supply chain

- Uses real-time data to manage operations and build a dependable, efficient supply chain

- Tracks and minimizes long and inefficient delivery routes to increase supply chain performance

- Extrapolates insights and devise a profitable financial plan

- Improves business forecasting by analyzing price fluctuation and route suggestions

- Groups similar products and plans your packaging better by using efficient space planning with package measurement data insights

- Uncovers redundant routes and decreases logistics waste by analyzing network hubs, bottlenecks, warehouses, and other logistics elements

Overall, logistics Intelligence helps a business improve its decision-making process with real-time, accurate data. Business intelligence tools convert data into digestible chunks of information and represent the information visually to help with faster decision-making.

How To Use Logistics Intelligence To Optimize Supply Chain Processes

Diverse goals and disconnected processes in large value chains make end-to-end optimization challenging.

Logistics Intelligence brings independent supply chain processes and unifies them to work as one integrated unit to achieve its end goals and enhance supply chain visibility. Let’s look at how to use this visibility to build agile supply chain companies.

How to Leverage Reporting in Logistics Intelligence To Build Faster Supply Chains

Having easy access to detailed reports with transport provider’s data, including metrics like weight, package dimensions, expected delivery time, tender acceptance rate, etc., solves half the worries.

It makes tracking supply chain systems more accurate and faster.

Logistics Dashboard reports can be generated instantly.

Visualization tools like these sync the objectives together and bring clarity to crucial economic decisions and opportunities.

Unlike traditional data mining methods, there’s no more waiting for weeks and months to study current trends and understand supply chain operations.

How to Use Real-Time Dashboards To Grow Your Supply Chain Business

Instantaneous data is the driving force behind robust, agile supply chains because they dramatically decrease monotonous human effort and save tons of time spent on mining voluminous data.

Let’s take an example of a mining plant. In case of a crisis like shortage of workers or regional connectivity, real-time data equips you with quick reaction time and ensures safety before it’s too late.

Similarly, let’s say a package is delayed due to freight arrival delay. If all the tracking data were left trusted with the 3PL or freight services like UPS or FedEx, you wouldn’t really know what’s happening with the freight cargo until there was a barrage of complaints from angry customers.

To avoid such an emergency, you could get ahead of your next action step with real-time tracking. If the freight cargo is getting delayed, dashboard data conveys that to you immediately. You can communicate with your customers beforehand and inform them of the causes of the delay and avoid bad reviews that hamper your brand’s reputation and cost you profits in the long run.

How to Optimize Supply Chains and Reduce Carrier Charges

The pandemic has triggered the eCommerce boom like never before.

High consumer goods demand has resulted in container shortages and soaring freight cargo charges. Global shipping rates have seen a record spike in recent months.

According to Freightos, the cost to ship a container from China to the U.S. East Coast in November was a shocking $4,750. It cost 42% less in July 2020. At this rate, soaring container charges can prove to be a huge impediment to supply chain companies. And the numbers are not going down anytime soon.

But, there is a way to reduce carrier costs. Let’s look at some cost optimization strategies:

Optimize Carrier Miles and Reduce Transportation Costs

Transportation cost amounts to a significant number in overall supply chain spending. Unfortunately, this cost is passed onto the customers. Product costs keep increasing, leading to decreased customer retention rate – and a reduction in revenue and profits. However, here’s how we can tackle rising transportation costs.

Use Fewer Carriers to Reduce Dead Miles

Having multiple carriers often gives good service. But if larger loads are assigned to a single carrier vendor, there is a possibility to lower rates across all routes. Not all individual routes will cost less than other carriers. However, if one considers all the routes and calculates the total cost, such an arrangement will work out to be cheaper.

The manufacturers can outline their requirements, roll out a quotation request, and evaluate different bidders for the job.

Having long-term contracts with carriers gives them time to shape up an efficient network with minimal or no dead miles, resulting in savings up to 3-5%. A contract for a longer duration also means locked-in rates, which otherwise may go up every year.

Load Boarding or Feight Boarding Can Save Costs

Imagine there’s a truck driver stationed in Kansas after a full load delivery from Georgia. He’s done his job, and now it’s time to head back home. But he’ll be clocking an empty load – which is a massive loss for small business owners like him.

Now, he has two options:

A. Head back home with an empty truckload and uncompensated miles.

B. Look for a return load on freight marketplace and maximize his profits by reducing downtime.

The latter option is a win-win for three logistics parties here – supply chain companies looking for carriers, truck drivers looking for load boards, and third-party carriers connecting supply chains with truck drivers.

For a supply chain company, having a load board for a one-off shipment can fetch you lower rates, especially if they are carried as backhauls. And sometimes, carriers may be ready to charge only fuel costs and a little extra for such loads to avoid empty miles cost.

Have a Steady Volume Contract to Reduce Recurring Charges

If you have a steady flow of freight for a repeat destination, the carrier can market and book return freight trips. Hence reducing the transportation cost significantly.

The added advantage is the priority given to suppliers who have regular freight volumes.

This is especially beneficial on days with tight transport capacity. You not only save in recurring carrier costs, but you’ll also save the extra costs that may incur during high-demand seasons.

Optimum Inventory Storage Reduces Variable Costs

For cost-effective operations, inventory should be replenished to an optimum number, consistently.

Now, why have an inventory stock?

To reduce supplier lead time and deliver products on time as and when the orders chime in.

Optimum stocking also means measuring and expecting order capacity to avoid overstocking, which results in losses.

Some of the factors to consider while calculating optimum inventory levels include:

- Demand variability

- Manufacturing time

- Transportation time

- Delivery lead time

Quick Tip: The safe amount of inventory is the quantity of goods/raw material that doesn’t affect the manufacturing cycle due to shortage of material or cost more for storage.

Reducing Sourcing and Storing costs

Finding a supplier who not only supplies raw material but also stores it until the raw material procurement requests begin is a smart way to reduce warehousing costs. This is called an Integrated Supply Chain System.

Contracting a single vendor for all logistics and transportation requirements can allow manufacturers to negotiate and reduce overall costs. The manufacturers can outline their requirements and roll out a request for quotation and evaluate annual contracts for efficient management. This system is called Single Sourcing, and it saves the manufacturer tons of time and money. Because there is no need to solicit and review bids from a variety of suppliers every single time there’s a transport request, it saves months in man-hours and hence reduces costs.

Consolidating Shipments

It is cost-effective to consolidate shipments to make Full container load (FCL) or Truckload (TL) going in the same direction. The other advantage of FCL or TL is that carriers load goods according to your specifications. This reduces the chance of custom delays in case other shipments in the container don’t adhere to government regulations. Consolidated larger shipments can give potential savings up to 50% as opposed to smaller shipments. For a small shipment, the shipper may end up paying a huge amount as minimum charges over a period of time. Sharing freight savings with the retailer may influence the retailer to book larger shipments.

Also, incentivizing larger shipments is not only cheaper, it’s sustainable.

When FCL or TL is not possible, then it is economical to consolidate shipment of size Less than Truckload (LTL) or LCL (Less than a Container Load) of one or more suppliers going towards the same destination.

Minimize Touch-Points

Big chain retailers procure their merchandise directly from manufacturers. As much as possible, individual merchandise should be touched only when a consumer buys it off the rack to reduce manpower and warehousing costs.

But how do you decide what logistics strategy applies right now for the current situation?

This is where logistics intelligence helps you map out current events and trends and derive the right information needed to pull out of an emergency/crisis quickly.

Arriving at an optimum inventory number depending on season and demand is impossible without a logistics intelligence system that displays historical trends and showcases supply chain behavior in a visual format.

Here’s how eSigns.com saved $375,000 in 12 months using Sifted’s LI platform. Request a free demo here.