The recent eCommerce boom has also triggered increased logistics and supply chain expenditure.

An increase in expenditure means a decrease in profitability – if your supply chain management is inefficient.

With socioeconomic changes, supply chains must adapt to demand-driven markets and maintain the expenditure-revenue-profit equilibrium with agility and robustness.

This can be achieved by balancing logistics and supply chain management.

But aren’t logistics and supply chain management one and the same?

Not really.

Although the two terms are used interchangeably, logistics is only part of supply chain management. Let’s look into it in more detail.

Relationship between Logistics and Supply Chain Management:

Supply Chain Management (SCM)

All processes from sourcing raw material, procuring customer requirements, transforming it into finished products, and delivering it to the end customer put together, is known as Supply Chain Management.

Logistics

Logistics is the process of acquiring, storing, and delivering finished products to customers on time at a competitive price.

Difference Between Logistics And Supply Chain Management:

Logistics refers to the activities of moving goods from one point to another, whereas supply chain management involves cross-functional and inter-enterprise processes.

The purpose of logistics is to provide on-time delivery, while SCM is to provide a product or service using efficient and cost effective methods.

Logistics processes include inbound and outbound transportation, storage, returns processing, and packaging.

While in SCM, the processes revolve around procuring, supplying, demand planning, resource planning, inventory management, manufacturing, logistics, and optimizing the product and processes.

Types of Logistics Strategies To Optimize SCM Processes:

Logistics operational strategies can either be product-specific / destination-specific / customer-specific.

There are six different types of logistics strategies:

1. Inbound Logistics

Inbound logistics is sourcing and transporting raw material from a supplier to the buyer’s manufacturing unit.

Managing suppliers, costs, warehousing, and transportation of components to the assembly line in time to manufacture the final product are the activities that make up inbound logistics.

2. Outbound Logistics

Outbound logistics is transporting and delivering the finished product in time to the customer.

Distribution channels and transportation systems have a vital role to play in outbound logistics.

ECommerce companies rely heavily on outbound logistics for fast and smooth customer deliveries.

3. Reverse Logistics

Products returning from customers fall under the reverse logistics category, also known as the aftermarket supply chain.

Product returns fall under these 4 categories:

- Defective products

- Product recalls

- Simple returns

- End-of-life products

Creating a return policy can reduce reverse logistics costs and limit the number of product returns.

4. Distribution Logistics

The connection between production and market is distribution logistics, also known as transport or sale logistics.

Interorganizational planning, realization, and transportation of goods aim to create an efficient logistics channel between a supplier and customer.

Distribution logistics is subcategorized into strategic, tactical, and operational tasks.

5. Third Party Logistics

Third-Party Logistics or 3PL companies are employed by the manufacturer to outsource warehousing and delivery to the end customer.

Third-party logistics suppliers are involved in transportation, storage, collecting, packing and packaging, inventory forecasting, fulfilling orders, freight forwarding, and reverse logistics.

6. Fourth Party Logistics

In Fourth Party Logistics, 4PLs in short, are involved in assessing, designing, running, and measuring solutions for customers.

A 4PL partner is the single point of contact between the manufacturer and the entire supply chain.

Factors Involved In Developing A Profitable Logistics Strategy:

1. Outsourcing

As a supply chain company, here are a couple of questions you should answer before devising a profitable logistics strategy.

- How does outsourcing logistics functions reduce supply chain management costs?

- What’s more profitable – Employing 3PLs and 4PLs in a particular zone or setting up a permanent warehouse?

- Alternatively, what partial logistics functions can be outsourced to improve services and delivery?

2. Transportation

- Is the current transportation strategy rendering good service?

- Is the current transportation strategy cost-effective compared to the other alternative transportation strategies employed?

3. Logistics System

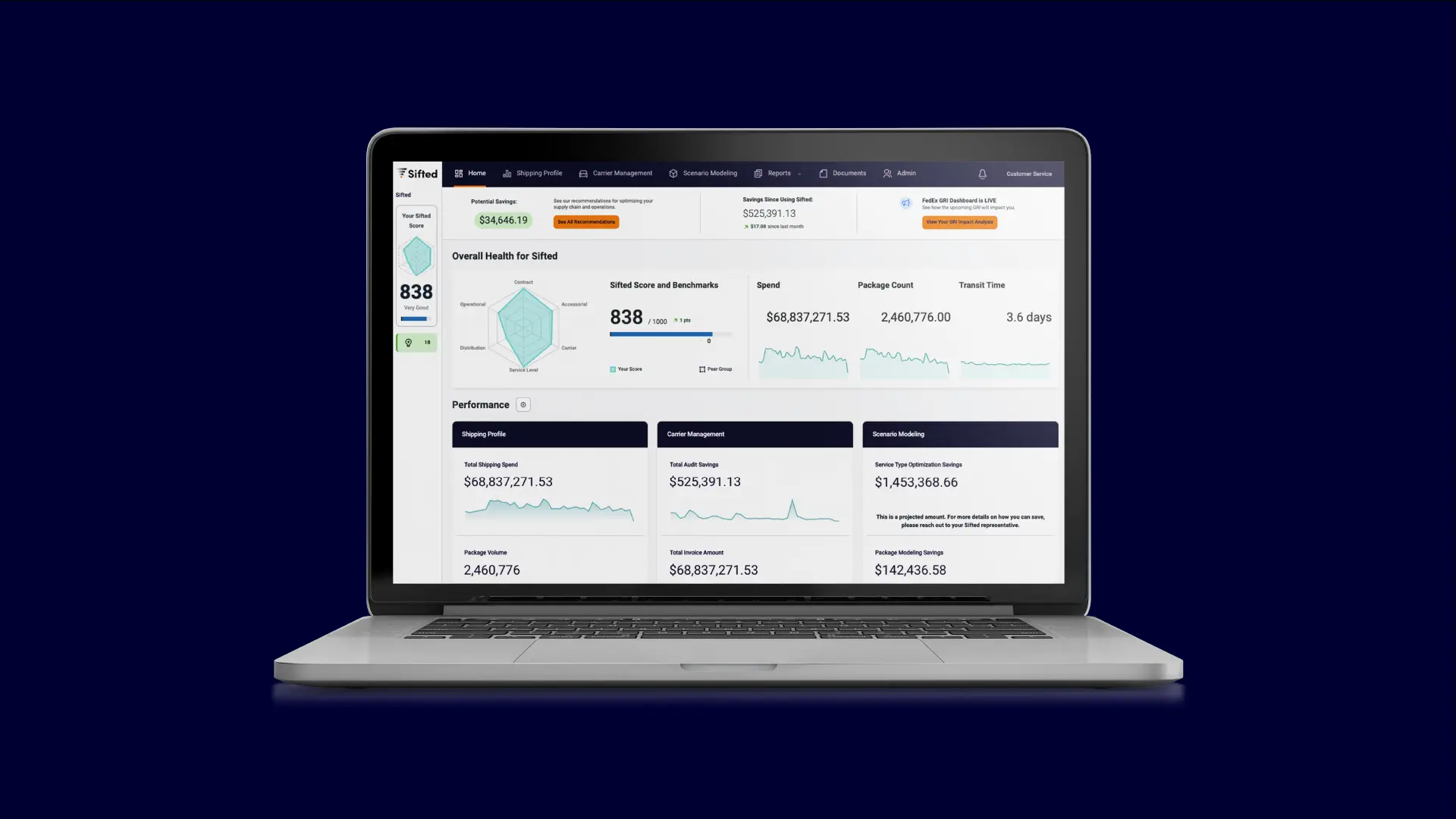

- Is the information system helping the logistics system procure, produce and deliver products on time?

- Is the sales management system customized to decrease expenses, manage data, and track locations with robustness and accuracy?

4. Strategy Review

Devising a supply chain strategy is not a straightforward, one-off task. It’s done in several iterations to constantly improve SCM operations.

- Do the organizational objectives and logistics goals align with each other?

- Do you have a system to break down conflicting objectives and arrive at collaborative solutions for integrating supply chains?

- Do you have measurable targets to evaluate the impact of supply chain actions?

- How credible is each of the third-party organizations you depend on? Have you calculated the financial, organizational, operational, and impact risk related to each of these connected organizations?

So far, we’ve looked at the factors involved in developing a profitable logistics strategy.

Now let’s look at the factors that influence logistics planning strategy.

Factors Influencing Logistics Planning:

1. Consumer Psychology and Logistics Planning

Imagine this – In an ideal setting, the manufacturer has an optimum inventory stock to keep the assembly line running without any hiccups or additional warehousing costs.

However, different customers have different needs at different times. Other factors like seasonal demands play a crucial role in the eCommerce economy. Therefore, forecasting can be a challenge in logistics planning.

That said, if you look at past logistics intelligence data and study consecutive company sales patterns and trends over a seasonal period, the logistics intelligence system gives a predictive analytical pattern to forecast demands even before they occur.

2. Distribution Network Strategy and Logistics Planning

Every logistics distributor’s dream is to achieve the ideal of fully loaded trucks operating on scheduled time and routes with 100% safety and accuracy.

And with proper planning and execution of distribution management and warehousing operations, the distributor can run a near-perfect, highly efficient, and profitable supply chain business with access to accurate logistics intelligence tools.

3. Communication Across Supply Chain Channels

Open communication between the supplier, buyer, and third-party mediators helps in inventory forecasting and replenishment according to staffing and transportation schedule.

4. Globalization of Trade

In international trade, the transit times are longer due to the geographical distance between buyers and sellers.

Sometimes, factors like culture, language, and business practices make it challenging to monitor and implement a linear logistics process. This slows down businesses.

However, supply chains can implement profitable logistics operations strategies to speed up business and trade.

7 Profitable Logistics Operations Strategies To Make Supply Chain Management More Efficient

Efficient supply chain management helps avoid delays in shipment and minimize logistical errors.

Strategies to deliver excellent customer service and achieve financial success in large supply chains:

1. Inventory and Return Management

Inventory Management

Maintaining optimum inventory even during fluctuating demand seasons makes the supply chain cost-effective.

Optimum level in inventory is achieved when there is no shortage of raw material affecting the manufacturing cycle or overstocking, resulting in higher warehousing costs.

Demand variability, manufacturing time, and transportation time are the factors to consider while calculating optimum inventory.

Return Management

Tracking every return is essential to efficiently reprocess or refurbish the product.

A supply chain discrepancy can be identified and rectified by using an efficient returns management system.

For instance, the return of a single product from a batch is a minor issue.

However, the return of multiple products due to the same reason can flag an entire shipment. Therefore, it helps to have an efficient return tracking system that segments the return product based on threat category in order to save the shipment lot from endangerment. It helps to discover the problem and fix it in the initial stages.

How to Stay Ahead of Reverse Logistics Costs

2. Warehouse Management

The aim of warehousing should be minimum wastage and maximum storage capacity.

Implementing an effective warehouse management system helps in sequencing, storing, and locating products in as little time as possible.

Optimizing DC operations to improve productivity by maximizing vertical space rather than space expansion is one of the smart ways to turn warehouse management into profitable operations.

3. Cash Control

Healthy cash flow is a key indicator of the financial health of any organization. Let’s look at the prime cash flow KPIs that determine the success of a SCM.

Supplier Cash Control

Like mentioned before, most eCommerce businesses rely on manual order processing even in this age and time. Creating an automated order placement process avoids hefty correction costs during post-processing of orders and payments.

The payment terms with the supplier ought to be analyzed and optimized for profitability and future loss aversion.

Customer Cash Control

Automating customer order processing and delivery reduces errors in the manufacturing and supply process, and hence eliminates compound losses.

Reducing the time between order placement, delivery of goods, and payment is what speeds up your supply chain and the profitability in the organization. These are simple tips, but often ignored because they’re not simple to implement.

However, if you’re looking for help with automating your supply chain, book a free demo with Sifted now.

Optimizing payment terms and settlements, keeping track of delayed and missing payments, and sending invoices on time make for a seamless customer experience – resulting in easy customer retention. Retaining customers is 12X more profitable than acquiring new customers as an eCommerce business.

4. Operating Expenses Control

A simple but often overlooked rule – minimizing incorrect supplies not by just correcting the particular order, but by finding out the point of error will go a long way in controlling operational expenses.

5. Dependable Suppliers

Cost and reliability go hand-in-hand when procuring from a supplier.

Identifying and sealing a deal with suppliers with consistently high standards of product quality, customer care, and customer experience is of utmost importance to your supply chain to profit easily in the long run.

6. Employee Development

Employee development shouldn’t be limited to formal education. It should extend to on-the-job training, mentoring, and task rotations to keep employees interested and growing.

This also helps employees understand the processes and big picture impact each one of them is creating inside this business.

Regular training keeps employees up to date and increases their efficiency, which in turn snowballs customer satisfaction from your brand.

7. Efficient Transportation through Digitization

Two crucial factors that make transportation efficient are:

A. Finding the safest, shortest, and best route for faster delivery

B. Finding cost-effective, optimized packaging that does not increase volume and/or weight

Stop overspending! Save your spend by digitizing and optimizing your supply chain. Book a free demo here.