Climate change is impacting production costs, reducing delivery speed and affecting the quality of goods delivered to the end user. Unpredictable natural disasters arising due to climate change are increasing the fragility of the supply chain industry.

But, the irony is, the supply chain and shipping industry contributes to a staggering 80% of the global greenhouse gas emissions causing climate change.

CO2 emissions boost global warming, causing ocean temperatures to rise.

When temperatures rise, warm waters cause intense hurricanes that disrupt the supply chain industry and derange global commerce trade.

In a case study, McKinsey says that climatic hazards are inevitable. But, with worsening climatic conditions, shipping delays and supply chain risks are only going to get worse from here.

How to Reduce Shipping Delays and Supply Chain Failure Due to Climate Change

- Stabilize your supply chain operations

- Make your supply chain sustainable

- Reduce economic backlog by reducing shipping dependencies

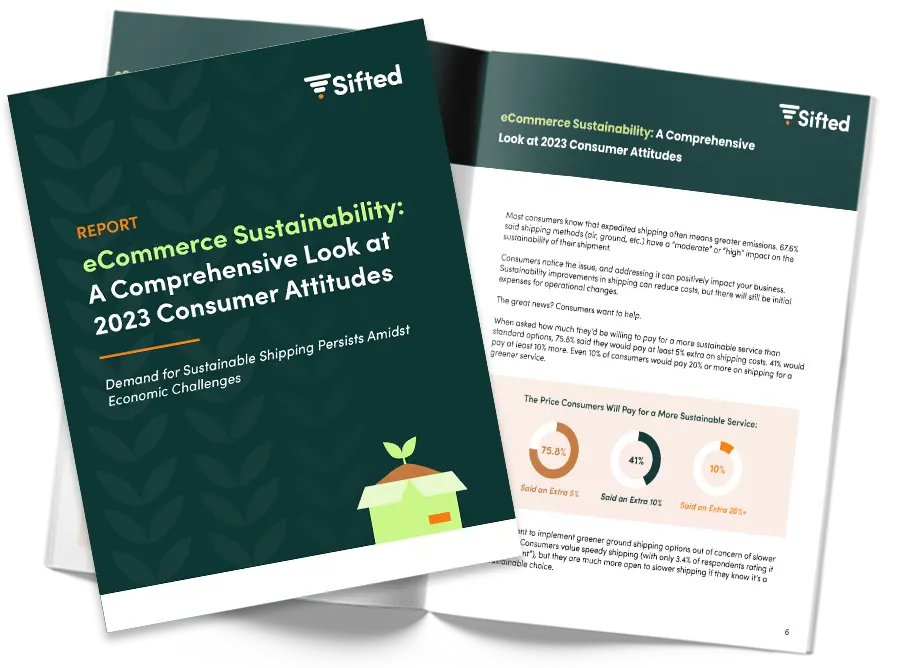

Report: 2023 eCommerce Sustainability

1. Stabilize Your Supply Chain Operations

The pandemic forced the supply chain sector to come to a temporary halt during the initial days.

Due to lockdowns, the flow of raw materials impacted production in manufacturing plants. This delay racked the trade and transportation of finished goods which affected sales heavily.

The same thing happened during the wildfires that struck California in 2020. People were evacuated, property was damaged, rail lines and trucking routes were inevitably shut down.

Not to forget, the latest maritime traffic choke in the Suez Canal that deranged global trade and economy for a week. The stranded Ever Given cargo vessel was costing $6.7 million every minute, accounting for a total loss of $54 billion in world trade.

Events like these not only disrupt day-to-day life, they also paralyze the logistics sector. Eventually, the supply chain system suffers compounding effects.

This exposes the vulnerability of the current distribution network – which is officially running the world economy right now.

So how can we stabilize our supply chain operations proactively?

- Plan ahead for better coverage and security

Track and analyze forecasting data and plan your manufacturing process ahead of unfavorable weather conditions. For example, when the 2017 hurricanes hit Bermuda, the region suffered an estimated loss of $330 billion. Out of that, goods accounting to only about $130 billion were covered by insurers. - Have a risk mitigation strategy in place

While businesses were incurring billions of dollars in losses during the 2017 hurricane season, General Motors evaded this deficit. GM used data to predict hurricane occurrences. They devised a risk-proof production plan and worked out a deal with their suppliers to pre-produce their inventory way ahead in time.They didn’t stop there.They also predicted how the inventory would be banked or shipped earlier so that they avoid losses and prevent business backlogs. And, it worked perfectly. It not only saved General Motors billions of dollars of losses, this move helped them pocket profits despite uncertain conditions. - Revisit the bigger picture

In 2021, the supply chain is less about tracking the insides of your boxes and more about securing your shipment by tracking data.The current supply chain system is complex – with way too many hierarchical dependencies across verticals. By tracking, analyzing and systemizing the supply chain, you avoid inefficient shipment movements including delays and penalties.

Case study: How BHF saved $500,000 by bringing down their gross parcel spend by 15%

2. How to Make Your Supply Chain Resilient and Sustainable

Sustainability is consistent innovation, and development to meet the current needs, without compromising the future of the generations to come.

This begs the question: Is our present supply chain industry sustainable?

Think about it.

It’s time to evaluate our choices and assess our business operations to build an ecologically viable supply chain system.

The metals industry sector expels an estimated 300 million tons of toxic waste into rivers every year.

Let that sink in.

In addition to that, the chemicals and fertilizers industry contribute to 30% of reduction in biodiversity every year. That’s appalling!

In an attempt to tackle loss in biodiversity and pollution, the EPA urges large corporations to adopt these pillars of sustainability:

Environmental Sustainability

This pillar focuses on protecting natural habitats, restoring ecosystems, reducing generation of dangerous chemical waste, minimizing greenhouse gas emissions, reducing water contamination and recycling resources as much as possible.

Social Sustainability

This pillar is an extension of the first pillar. It puts human health on the forefront. And emphasizes making community health a corporate responsibility.

Embodying this principle is the only way to protect, maintain and restore access to basic resources like food, water and land for the local communities. Especially to communities who are burdened by industrial pollution.

Economic Sustainability

The EPA is encouraging industries to develop waste-free processes and green energy sources – which eventually eliminate the need for fossil fuels, compliance costs and reduce the company’s overall costs.

3. Resort to Lean Manufacturing to Reduce Shipping Dependency and Economic Backlog

In 2012, the Association for Manufacturing Excellence released a report on Nike’s Lean Production success.

The report explains how Nike’s Lean Manufacturing process reduced material waste, production time and delivery lead time while improving labor conditions.

What is Lean Manufacturing?

In simple terms, lean manufacturing is innovating to reduce waste, cut costs and model profitable growth while minimizing environmental risks.

Lean manufacturing is an improvisation of the original Toyota Production System (TPS) manufacturing model.

The TPS is based on the “just-in-time” production philosophy which cuts down production and delivery cycles by a significant margin. This not only lowers the cost to the company, it also eliminates overproduction risks, and penalties, especially during unprecedented times.

This system works because you’re planning and producing only based on demand. Therefore, you have better tracking processes that avoid unnecessary mobility of goods, raw material and labor. This significantly reduces economic backlog since there’s no excess inventory or redundant logistics. Logistics contribute to a large part of the air pollution and noise pollution problem.

Quick Fact: Did you know that noise pollution melts glaciers, causes flooding, and threatens ecosystems? Don’t believe it? Here’s the proof.

How climate change makes the supply chain industry more susceptible to penalties

In January 2020, the International Maritime Organization 2020 mandate came into force. IMO 2020 demands all types of ships to limit sulphur content in their fuel oil.

In a quest to protect the environment and save the local ports and marine environment from pollution, IMO member states have also taken measures to limit or restrict discharge of ship washwater.

While countries like Israel and New Zealand are yet to sign up for the IMO 2020 agreement, European countries have already begun rigorous oil sampling procedures in their local ports and shipping docks. Non-compliance to IMO 2020 standards holds a threat of imprisonment in Europe.

The point is – impact of climate change on the supply chain industry and vice versa is a vicious cycle. Organizations like IMO are partnering up with countries to reduce environmental pollution by bringing transparency to the system.

The intent of IMO 2020 is to prevent environmental hazards caused by the maritime industry and non-compliers may pay a heavy price. Complying to IMO 2020 is not just about avoiding surprise costs and penalties. It’s about finally focusing on the environment and actually saving the supply chain industry from a permanent collapse.

The Future of the Supply Chain Industry

Simplifying supply chains, adopting sustainable packaging, optimizing business operations to enable global connectivity – without compromising the natural ecosystems is the future.

Eliminating third party dependencies creates efficient business operations and has a higher chance of collaborating with suppliers to innovate business processes that work towards greener alternatives.

Lean, streamlined supply chains prove to be more profitable in the long run as they consistently reduce overhead costs.

Using data systems to track and approve demand forecasts can help avoid production bottlenecks and shipment delays. Understand and future-proof your operations so you are set-up for success now and in the years to come.

Next Read: How to Reduce Shipping Costs by Adopting Sustainable Packaging Solutions in 2021