In 2017, ecommerce was responsible for $2.4 trillion in sales.

The numbers are expected to double in 2021.

In the United States alone, online shopping accounts for 10% of retail merchandise sales and is forecasted to grow at a 15% progressive growth rate, every year.

Growth in trade and commerce also means an increased load on supply chain logistics systems.

An overburdened logistics system can make it extremely difficult to give a good customer experience and can have a compounding effect on future sales.

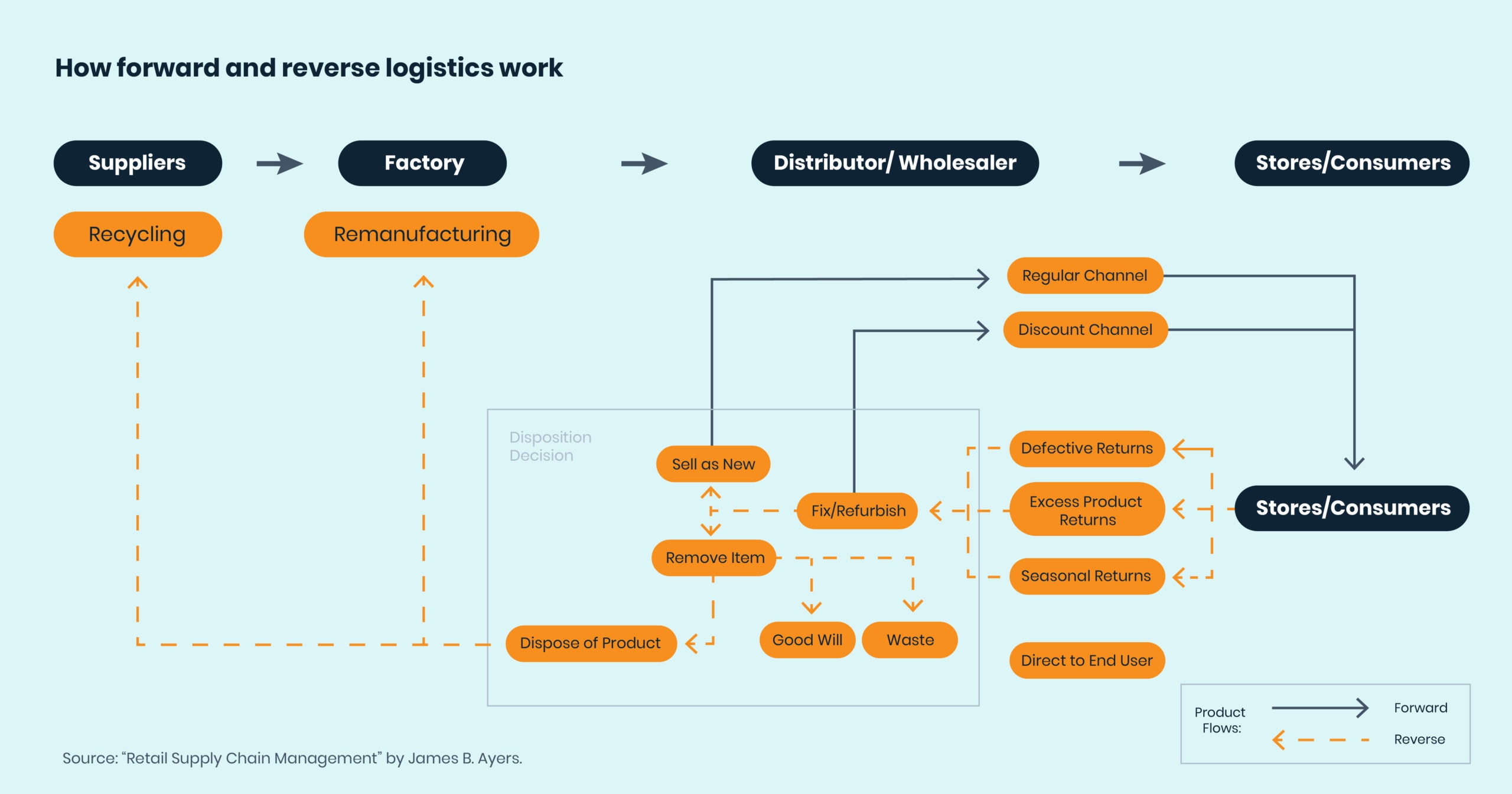

Therefore, to minimize customer grievances and to tackle plummeting sales, supply chain companies simplify their logistics by splitting it into two independent processes:

- Forward Logistics

- Reverse Logistics

What is Forward Logistics?

Forward logistics refers to the movement of the goods from the manufacturer to customers. It involves receiving an order, packaging the product, dispatching, and delivering.

However, there are several occasions when a customer files for a return for a variety of reasons. That’s when the reverse logistics process starts.

What is Reverse Logistics?

When customers file for a return, the returned products lose a part of their value and offer little ROI to the sellers.

Reverse logistics is the process of recapturing the value of returned goods and bringing them back into the marketplace as soon as possible.

When a product is returned, the manufacturer or reseller company collects the item for return and plans its next steps.

The returned products may be disposed of, refurbished, or resold to extend their lifecycle. This entire process of planning and managing the reverse flow of goods is called reverse logistics.

Get Your Reverse Logistics Costs Under Control

Difference between forward logistics and reverse logistics

Here’s a visual representation of how forward and reverse logistics work:

————————————————————————————————-

Optimized reverse logistics, when implemented correctly, can reduce the returns processing cost by 25% and increase productivity by 10%. It can further lead to significant growth in customer satisfaction and retention – thereby increasing net profits by 2 to 5%.

-Abhik Mitra, CEO Spoton Logistics on how improved logistics will improve business performance

Source: Financial Express

—————————————————————————————————

Why is it important to track reverse logistics activities

There are several reasons why consumers return a purchase.

In fact, 30% of shoppers deliberately over-purchase and return unwanted goods.

Fashion retailers are burdened by reverse logistics costs because almost 4 in 10 orders result in return.

Barclaycard reports that UK shoppers are returning £7 billion of purchases every year. The free return policy has given rise to a “Phantom Economy” where retailers are coping billions of dollars in losses.

Did you know? Research says that 30% of shoppers deliberately over-purchase and then return unwanted items. Do you know what makes people over-purchase? Share on X

Reverse Logistics Examples

Most common reasons why customers file for product returns are:

- Goods may be damaged or defective

- Product may be outdated or EOL

- Customer may not like the quality of the product

- The product may not match the description on the website

- It may have arrived late or the customer may no longer need it

- The customer may have changed their mind after receiving the product

- The merchant may have shipped the wrong item or size

- The product might be a result of over-purchase

- The product may have been recalled by the government

Quick fact: Surprisingly enough, only 20% of the product returns are truly defective returns. Other products being processed through a return center may be due to product recalls, end-of-life returns, or seasonal returns.

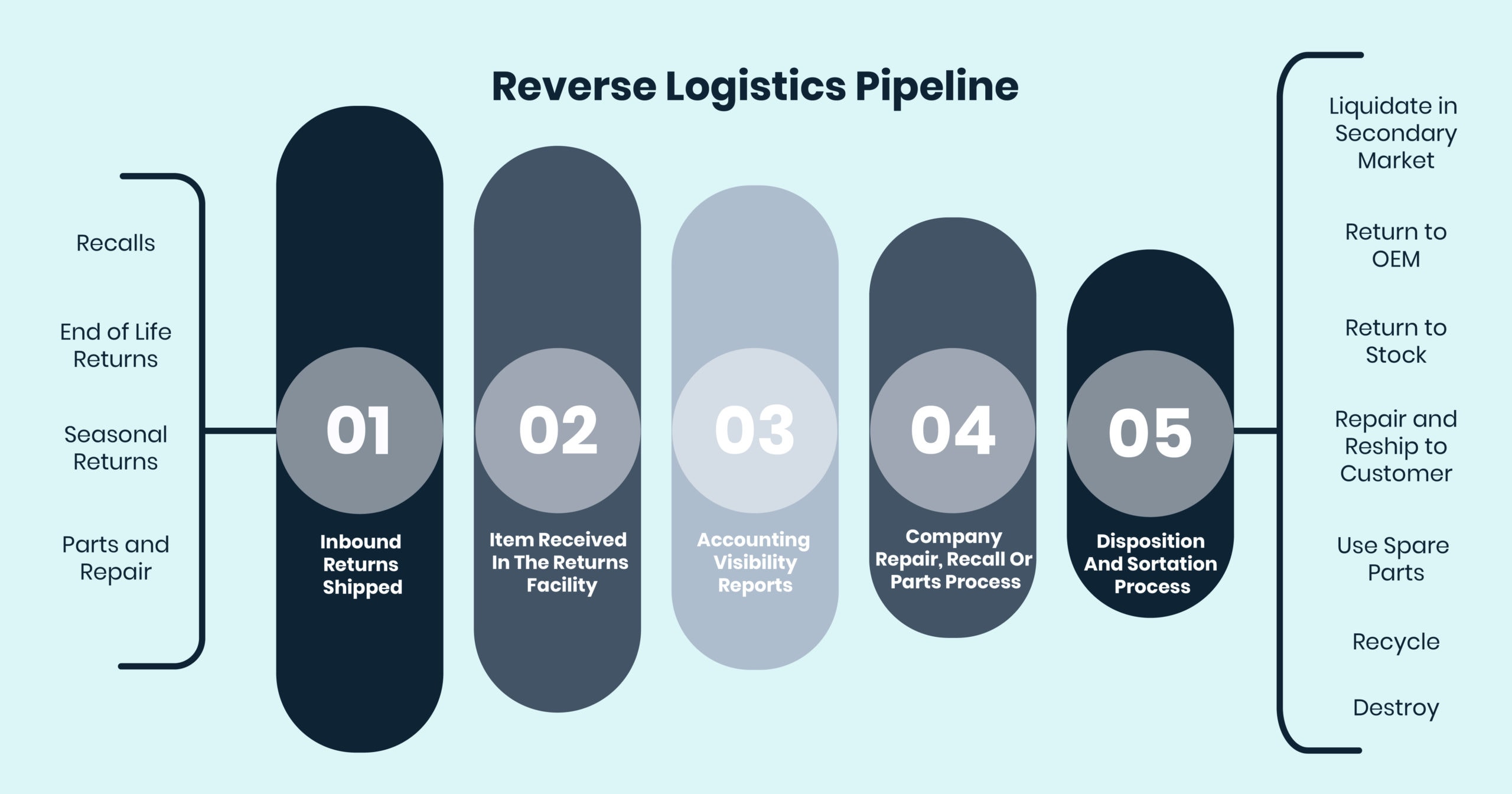

Reverse Logistics Pipeline

When you’re running a business, product returns are inevitable. In fact, customers return nearly 30% of all e-commerce products in comparison to 8.89% in brick-and-mortar stores.

The problem is – most logistics professionals and supply chain companies consider product returns as a necessary evil. So, they tend to be more forward logistics focused and ignore the several hidden costs associated with reverse logistics activities.

However, it is possible to reduce reverse logistics churn by implementing a smooth return process in the supply chain.

How To Optimize Reverse Logistics To Reduce Churn

Lack of optimum reverse logistics management can hurt ecommerce businesses.

Implementing simple reverse logistics best practices can save millions of dollars in supply chain costs:

- Include an identification number to track the returned product’s condition.

- Indicate refund status and implement policies to replace faulty goods

- Sort the returned goods into different post-return categories. For example, just being able to know whether the goods need to be replaced, fixed, or resold will save hours of time and millions of dollars.

- Have a system to fix products. Any product that is fixable should be sent to the repair department. This not only saves the company a huge chunk of revenue, but it also helps save the planet by reducing disposal waste from industries.

- In the case of an industrial product deemed non-repairable, examine the condition of its individual parts and sell it as a standalone product.

- The rest of the non-repairable industrial parts should be recycled or disposed of appropriately.

The Common Reasons Behind Excessive Reverse Logistics Costs

While most supply chain companies make continuous efforts to improve their logistics, they often tend to overlook reverse logistics.

This is due to the perception that product returns are inevitable. Therefore, the entire focus shifts towards improving forward logistics while neglecting reverse logistics.

In the process, companies fail to minimize shipping costs and package delays. They fail to have a set deadline to return the products to the manufacturer. And sometimes, companies don’t know how to forecast the return volume and reduce churn.

Not streamlining the reverse logistics processes leads to several hidden costs, making it difficult to identify the loopholes in the product life-cycle.

How to Improve Supply Chain Processes and Reduce Reverse Logistics Churn

Here are the 6 supply chain strategies to reduce reverse logistics costs:

- Regularly review and revise return policies: The policy should also consider the nature and cause of repairs and returns.

- Collaborate with your suppliers: It can ease the return process by allowing one point of contact for returns and improve the customer experience.

- Track the manufacturing process forward and backward: Keeping track of the raw materials used in each finished product and customer order can save months of time. In case of a discrepancy, the decision to recall the entire line or issuing selective recall status becomes simpler and easier.

- Centralize the return centers: Centralize and categorize the returned items and make it easier to recognize the best next step to recapture the value of returned goods.

- Monitor logistics and transportation: Tracking your logistics can save you repetitive trips, minimize shipping costs, and help supply chain companies reduce churn.

- Invest in Data Analysis: Analyze and understand the reason for return requests, and improve your product life cycle.

Data analytics helps track, manage and review your expenditure. This data helps you make critical business decisions faster by reducing guesswork and churn. It reduces asset recovery time and increases delivery accuracy – which in turn brings down your logistics costs by a significant margin.

Need help setting this up? Get all the info here.